Difference between revisions of "Stock Locations"

| Line 7: | Line 7: | ||

A Stock Holding is the smallest group of product items that can be held in stock, and is uniquely identified by the following values: | A Stock Holding is the smallest group of product items that can be held in stock, and is uniquely identified by the following values: | ||

* Product Code | * Stock Location | ||

*Product Code | |||

* Item Style | * Item Style | ||

* Unit Size | * Unit Size | ||

| Line 25: | Line 26: | ||

A Stock Location represents a single physical location holding one or more stock holdings. Generally, stock locations represent racks, shelves, bins or pallets that hold stock in a specific place within the warehouse. | A Stock Location represents a single physical location holding one or more stock holdings. Generally, stock locations represent racks, shelves, bins or pallets that hold stock in a specific place within the warehouse. | ||

A stock location can be marked as either "permanent" or "temporary" location. Temporary locations (eg a pallet or shipping container) represent stock that is generally reserved for a specific job or task, and is automatically | A stock location can be marked as either "permanent" or "temporary" location. Temporary locations (eg a pallet or shipping container) represent stock that is generally reserved for a specific job or task, and is automatically marked as "Inactive" of when the stock holdings contained in it are exhausted. By contrast, permanent stock locations (eg a shelf or a rack) exist over a long period of time, and remain active whether or not they actually have stock holdings. | ||

It is possible to change the Area and Warehouse (see below) of a stock location - this is done when temporary stock locations are moved from one physical location to another, or when the warehouse is reconfigured over time. By allowing the location to be moved (rather than being deleted and re-created), the historical record of item movement in and out of the location can be maintained, | It is possible to change the Area and Warehouse (see below) of a stock location - this is done when temporary stock locations are moved from one physical location to another, or when the warehouse is reconfigured over time. By allowing the location to be moved (rather than being deleted and re-created), the historical record of item movement in and out of the location can be maintained, eliminating the possibility of data loss. | ||

A location can be marked as "Default" for its current Area and Warehouse - if this is the case, then products received into stock are by default moved into this location. This is useful when defining a "Receivals Bay" for incoming goods - the Purchase Order / Consignment can be quickly received into this location, and the individual items subsequently transferred to their final locations at a later time. | |||

=== Areas === | === Areas === | ||

A Stock Area represents a group of Stock Locations (shelves, racks, bins) in a particular location. | |||

Areas that are currently in use should be marked as "Active" - this allows the area to appear in the various lookup lists for locations and product lookups. Empty or unused areas should have this flag turned off to help manage large numbers of stock areas | |||

=== Warehouses === | === Warehouses === | ||

A Stock Warehouse represents a group of Stock Areas, grouped by either physical location, purpose (or a combination of both). This enables | |||

Like Areas and Locations, warehouses can be marked as either "Active" or "Inactive" - this allows for unused Warehouses to be hidden from view without losing history information. | |||

=== Movements === | === Movements === | ||

Revision as of 02:26, 18 October 2022

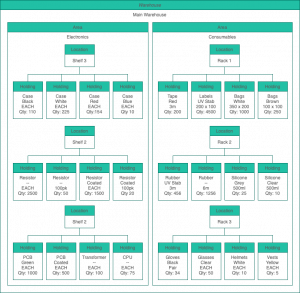

Overview

The PRS Stock warehousing system is built on the concept of stock holdings, which are groups of products of the same catalogue number, style, size, held in a particular location. Holdings within PRS are automatically created as products are received into the warehouse, and closed off once the products within that holding are issued from the warehouse. Holdings are grouped into Locations, which can in turn be grouped into Areas and Warehouses, allowing scalability of the system from a simple, single-location store to a distributed multi-warehouse network.

Holdings

A Stock Holding is the smallest group of product items that can be held in stock, and is uniquely identified by the following values:

- Stock Location

- Product Code

- Item Style

- Unit Size

- Job Number

Holdings cannot be created or deleted directly, but are automatically maintained as stock movements are entered into the system, through one of the following actions:

- Receiving a Purchase Order or Consignment Line

- Completing a Requisition

- Transferring Stock Items from one location to another

- Changing the style of a stock item

- Allocating or changing the job number associated with the stock items (reserved stock)

- Issuing Items from stock to manufacturing

- Adjusting stock errors during stocktake

Locations

A Stock Location represents a single physical location holding one or more stock holdings. Generally, stock locations represent racks, shelves, bins or pallets that hold stock in a specific place within the warehouse.

A stock location can be marked as either "permanent" or "temporary" location. Temporary locations (eg a pallet or shipping container) represent stock that is generally reserved for a specific job or task, and is automatically marked as "Inactive" of when the stock holdings contained in it are exhausted. By contrast, permanent stock locations (eg a shelf or a rack) exist over a long period of time, and remain active whether or not they actually have stock holdings.

It is possible to change the Area and Warehouse (see below) of a stock location - this is done when temporary stock locations are moved from one physical location to another, or when the warehouse is reconfigured over time. By allowing the location to be moved (rather than being deleted and re-created), the historical record of item movement in and out of the location can be maintained, eliminating the possibility of data loss.

A location can be marked as "Default" for its current Area and Warehouse - if this is the case, then products received into stock are by default moved into this location. This is useful when defining a "Receivals Bay" for incoming goods - the Purchase Order / Consignment can be quickly received into this location, and the individual items subsequently transferred to their final locations at a later time.

Areas

A Stock Area represents a group of Stock Locations (shelves, racks, bins) in a particular location.

Areas that are currently in use should be marked as "Active" - this allows the area to appear in the various lookup lists for locations and product lookups. Empty or unused areas should have this flag turned off to help manage large numbers of stock areas

Warehouses

A Stock Warehouse represents a group of Stock Areas, grouped by either physical location, purpose (or a combination of both). This enables

Like Areas and Locations, warehouses can be marked as either "Active" or "Inactive" - this allows for unused Warehouses to be hidden from view without losing history information.

Movements

PRS Desktop

PRS Mobile

See also: